Steel Structure Coal Shed Design-High Quality Tensile Membrane Roof

April 15,2020

In some countries with abundant mineral resources, due to the huge amount of output, they occupy a lot of places. Many open-air coal mining cities, because of the large amount of land occupied, seriously damage the environmental hygiene. With the development of the coal industry and the improvement of national environmental protection requirements, large-capacity coal sheds, coal bunkers or fully enclosed coal storage yards have become necessary to improve environmental protection.

In the field of large-scale construction, closed coal yards, landfills, sewage treatment plants, and some places where the environment is deteriorating, it is necessary to popularize coal sheds, inflatable membranes and tension fabric canopy.

Textile Membrane Coal shed. With steel structure and membrane structure as the carrier, the span is large, and it is covered with a layer of PVC membrane. It has excellent self-cleaning function, not only has good chemical resistance, high temperature resistance, oxidation resistance, weather resistance, and radiation resistance. In addition to radiation performance, it also has special properties such as piezoelectricity, dielectricity, and thermoelectricity.

Mechanical properties: The thickness is between 0.8-1.2mm, the tensile strength is 5000-8000N / 5cm, and the tensile strength is half that of steel.

Optical performance: The light transmittance can reach 6-8%, the transmitted light produces uniform diffused light inside the structure, without shadow and glare.

Fire resistance: It has excellent flame retardancy and high temperature resistance, meeting the fire protection requirements of many countries such as China, the United States, Japan, France, and Germany.

Self-cleaning performance: easy to clean attached stains, rainwater will gather on the surface of the water and flow down, so that the membrane surface can be cleaned naturally.

Corrosion resistance: resistant to various strong acids and alkalis, non-flammable, and aging resistant.

Therefore, coal sheds built with types of membrane structures are more environmentally friendly than traditional buildings.

Modern High Quality Membrane Construction ,Fabric Building in Kazakhstan

April 03,2020

The Republic of Kazakhstan is a landlocked country located in Central Asia, with an area of 2,724,900 square kilometers, accounting for about 2% of the earth's land surface area, and the territory spans Asia and Europe. The total length of the national border is more than 10,500 kilometers. It is the largest landlocked country in the world. The name of the country comes from its main ethnic Kazakh.The flexibility of the tensile architecture structures is just right for it.

Fabric structure buildings breaks the traditional architectural structure and has beautiful shapes, elegant nature, art and mechanics. It can give full play to the architect's imagination and create a variety of shapes with rich colors. The membrane structure is known as the 21st century Modern high-tech green building.

1. Thrifty energy

The architectural membrane material itself has good light transmittance, and the light transmittance is about 7% ~ 20%. No artificial lighting is required for daytime applications, and it can fully meet the needs of various sports competitions and other activities; the refractive index of the tensile shade structures material to light is above 70% Under the sunlight, soft astigmatism forms in the room, giving a comfortable and dreamlike feeling.

2. Secure application

Because of its light weight and good seismic performance comparison; the modern shade structure is a flexible structure that can tolerate large displacements and is not easy to collapse; and the membrane material is generally flame retardant and is not easy to cause fire.

3. Wide range of applications

In terms of area, fabric roof structures can be as small as a single tent, a garden piece, or a building covering tens of thousands or hundreds of thousands of square meters.

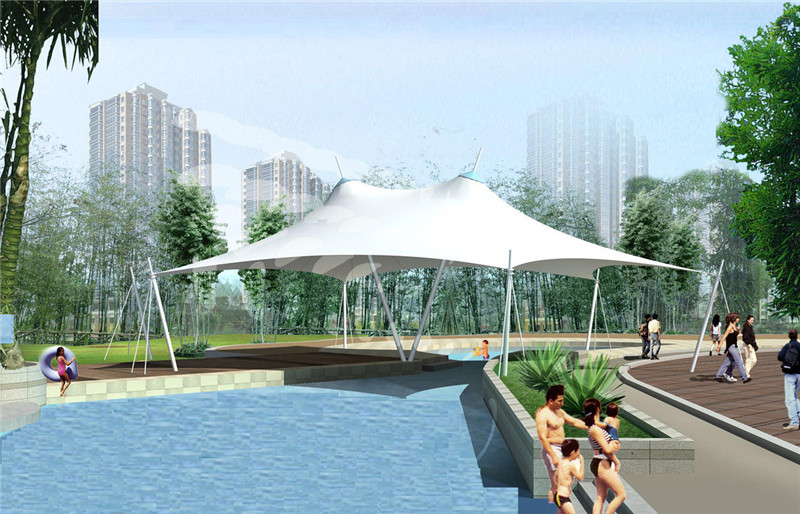

Supporting Facilities for Residential Areas with Modern Shade Structures in Gambia

March 27,2020

The Republic of the Gambia is located at 13 ° 28 'north latitude, 16 ° 39' west longitude, western Africa, and west of the Atlantic Ocean. The coastline is 48 kilometers long and covers an area of 10690 square kilometers.

In terms of the shelter structures itself, in addition to its unique decorative effect, it can be more difficult to meet the requirements of other architectural forms through its rich and convenient form. In addition to some iconic buildings (sculptures, flower beds, fountains, etc.) in a residential area, it must not lack necessary supporting facilities.

This is a comprehensive facility with leisure, entertainment, shopping and other facilities for owners who will stay in the community in the future. The space on the top floor is also fully utilized as an outdoor cafe. Similarly, the fabric tension building here will also be combined with lighting facilities, echoing the membrane structure on the roof of the residential building to form a colorful nighttime landscape of the community.

2. Entrance and exit of underground garage

At present, most middle-to-high-end residential areas have garages, and the use of membrane structures in the design of the entrance and exit of the garage is a creative idea. Although this medium-membrane structure garage entrance is no longer a new concept abroad, but the domestic membrane structure is still in an emerging stage. A newly designed and cleverly conceived membrane structure garage entrance not only plays the building performance of ordinary building materials, but also adds highlights to the community environment.

With the acceleration of urban modernization, cars have become an indispensable means of transportation in any city. Due to the rapid development of the automobile industry in China, the number of cars owned by cities has increased exponentially, but urban construction planning has not been able to adapt to this development requirement as quickly as possible, and often there is no place for parking. Therefore, the issue of parking lots should be fully considered in the planning of construction groups, and the construction and planning of parking lots as an important part of modern urban construction planning has become increasingly important. Similarly, fabric structures also play an important role in the construction of parking lots.

People living in modern cities have stepped from the past social behavior for the purpose of earning a living to a new level for the purpose of "music life", and have pursued a spiritually healthy, pleasant and humane cultural environment. The modern built environment is a comprehensive representation of modern cities, modern culture and society, and the lives and concepts of modern people. In terms of showing people's individuality, self-entertainment and diversified environmental spaces, the membrane structures architecture, with its unique architectural form, will surely be used more and more widely in environmental construction.

How is the Membrane Architecture Increase Stability in Philippines?

March 20,2020

The Republic of the Philippines is located in the Western Pacific. It is a multi-ethnic archipelago country in Southeast Asia, with an area of 297,700 square kilometers and a population of 110 million.

How to strengthen membrane structure building? In daily life, the canopy construction we use the most is even a parking shed. In some areas, wind and rain are frequent. At this time, we need to strengthen the membrane structure parking shed according to actual needs.

The main structure of most tensile roof structures parking sheds is a metal keel and a membrane top structure. The metal keel is connected with a metal bracket and the ground plane. The area of the ground plane is the key to the stability of the membrane structure parking shed. We can usually add stainless steel columns The method to increase the firmness of the parking shed is as follows: Add a foundation of 15-20 cm near the original metal pillar 5-10 cm, install a stainless steel pipe with a diameter of not less than 5CM, and the keel support on the top of the shed Welding is the most effective way to strengthen it.

We can also reduce the resistance to wind and rain by changing the membrane material with higher toughness and smoothness, and increase the tension of the fabric shelters in disguise to increase the firmness.

We also have a little trick to increase the firmness of the membrane structure parking shed, because the reason for the formation of the membrane structure parking shed is that the roof is spread out according to the tension of the membrane material, so we can connect the roof with stainless steel pipes. This can effectively resist the attack of wind and rain.

The above is the answer to how to strengthen the membrane structure building.

The Most Commonly used Membrane Material in Fabric Tensile Structures

March 16,2020

1.PTFE membrane material

PTFE membrane material refers to a composite material formed by coating PTFE (polytetrafluoroethylene) resin on a base cloth woven with ultra-fine glass fibers.

Its characteristics are: high strength, good durability, fire and flame retardant, good self-cleaning, and not affected by ultraviolet light, the service life is more than 20 years; it has high light transmittance, light transmittance is 13%, and transparent The light passing through the membrane material is naturally diffuse and does not produce shadows or glare. The reflectivity of solar energy is 73%, so it absorbs less heat. Even in the case of sun exposure in summer, the interior of the building will not be affected. Too much impact.

At present, the development and application of this kind of membrane material are relatively mature abroad, and there are many manufacturers, such as Germany Mehler Company, Verseidag Company, Japan Taiyoko-gyo Company, Zhongxing Chemical Industry Co., Ltd., United States Chemfab Company, Saudi Arabia ObeiKan Company and so on.

PVC membrane material is a composite material formed by coating PVC (polyvinyl chloride) resin on the base fabric woven with polyester fiber. The strength and fire resistance of PVC film material have a certain gap compared with PTFE. The service life is generally 7 to 15 year.

In order to solve the self-cleaning problem of PVC membrane materials, PVDF (polyvinylidene fluoride) is usually applied on the PVC coating to form PVDF membrane materials.

ETFE architectural membrane is made directly from ETFE (ethylene-tetrafluoroethylene copolymer) raw material. ETFE not only has excellent impact resistance, electrical properties, thermal stability and chemical resistance, but also has high mechanical strength and good processability.

In recent years, the application of ETFE membrane materials can replace other products in many aspects and show strong advantages and market prospects. This membrane material has particularly good light transmission. It is called "soft glass" and is light in weight. %; Good toughness, high tensile strength, not easy to tear, ductility greater than 400%; strong weather resistance and chemical resistance, melting temperature up to 200 ° C; can effectively use natural light and save energy; good acoustic performance .The self-cleaning function makes the surface difficult to be stained, and the small amount of dirt can be taken away by the rain. The cleaning cycle is about 5 years.

In addition, ETFE membrane can be pre-made into thin membrane bubbles, which is convenient for construction and maintenance.

ETFE also has shortcomings, such as the external environment is easy to damage materials and cause air leakage, high maintenance costs, but with the construction of large stadiums, tourist venues, waiting halls, etc., ETFE highlights its own advantages.At present, there are very few companies producing such membranes. Only a few companies, such as ASAHIGLASS (AGC), Asahi Glass, and Cowell, Germany, can provide ETFE membranes. The research and development and application of this membrane are not more than ten Years of history.

If you want to learn more about membrane structure engineering, welcome to BDiR Inc.

What are the Construction Methods of Membrane Structure Canopy in Bahamas

March 13,2020

The Bahamas lies east of Florida in the United States and north of Cuba and the Caribbean. The Bahamas contains 700 islands and coral reefs. Opposite the southeast coast of Florida, north of Cuba. The archipelago extends from northwest to southeast, with a length of 1220 kilometers and a width of 96 kilometers. It consists of more than 700 islands and more than 2,000 coral reefs. The total area is 13,878 square kilometers, of which more than 20 islands are inhabited. It has a subtropical climate with an average annual temperature of 23.5 ° C.

What are the construction methods of the outdoor shade cover? The success of the membrane structure canopy building, in addition to looking at the overall appearance and stability of the overall quality, the treatment of details is also very important. The quality of the welding of the membrane structure also plays a decisive role.

People often marvel at the magnificence of membrane structure buildings when they admire roof fabric, and when they see the sketches of membrane structures, they are deeply attracted by their dexterity and elegance. However, in actual construction, whether it is a large-scale membrane structure venue of tens of thousands of square meters, or a small piece of membrane structure of several square meters, it is not only composed of a single piece of membrane material, but is formed by splicing many membrane pieces.

The welding methods are hot gas welding, heating unit welding and high frequency welding, and the welding connection structure has the following methods:

First. One-sided welding of diaphragms of the same material and thickness, or two-sided welding of poor covering diaphragms.

Second. The double-sided cover membrane is staggered into thicker contacts. Staggered contacts can reduce the discontinuity of load transfer.

Third. The diaphragm with the same material and thickness is used, but the cover diaphragm is divided into two half layers and welded on both sides, so that the load can be smoothly transmitted.

Fourth. After cutting the membrane structure membrane into a tooth shape and connecting, the link length for transmitting load can be increased.

Fifth. The contacts of the high-strength double-layer membrane can be formed with thicker contacts by double-sided staggered covering membrane.

The above are the answers to the construction methods of membrane structure canopy welding. If you want to know more about membrane structure engineering, please consult BDiR Inc.

How to Design Drainage for the Fabric Architecture?

October 12,2020

How to design drainage for membrane structure building? After the tensile membrane structure is generally built, it will face many different types of weather, of which rainy days are inevitable, so drainage is the key point, and good drainage design is the key point.

How to design drainage for canopy architecture.Membrane structure building design should reasonably determine the drainage slope and drainage position according to the use characteristics of the building and the general plane requirements to ensure smooth drainage of the membrane surface; in areas with heavy snow loads, a larger membrane surface gradient and necessary Snow protection measures.

Tensile membrane structures drainage design can use unorganized drainage or organized drainage. Due to the peculiar shape of the membrane structure building and the free-form surface, the reasonable way of modeling and drainage should be fully considered. Textile architecture drainage slope requirements are greater than general buildings. The flat film slope is more than 15% ~ 20%, and the hyperbolic membrane ridge should be greater than 10%. At the same time, the pretension of the membrane surface is above 1.0 ~ 2.0 Thousand Newtons per Meter, which prevents the membrane material from undergoing large deformation under the action of rainwater, thereby causing water accumulation and water pockets on the membrane surface.

Membrane area water has the characteristics of Matthew effect. The accumulated water will cause local depression deformation, which in turn will aggravate the phenomenon of accumulated water. Sufficient slope, curvature and tension levels are necessary to ensure smooth drainage. The design of membrane structures such as aqueducts, aqueducts, and downspouts should be coordinated with the structural design of membrane nodes.

Large-scale public membrane structure buildings (3000 square meter) or more should adopt organized drainage; small open membrane structure buildings (under 500 square meter) can adopt unstructured drainage; medium-sized public membrane buildings (500 square meter ~ 3000 square meter) should be based on their elevation, confinement and open Select appropriate drainage form, partly free drainage and structural organization drainage.

The above is the answer to how to design drainage for outdoor shade covers structure. If you want to learn more about membrane structure engineering, welcome to follow BDiR Inc.

Why Choose a Tenile Fabric Structure Ceiling & Indoor Roof?

March 20,2020

The soft film ceiling (Tensile Fabric/Membrane ceiling) adopts white PVC or PTFE Mesh membrane material, and is mounted on the steel frame keel through aluminum alloy or stainless steel accessories. With the development of the times, tensile film ceiling has become the most popular new type of environmental protection ceiling styles. Its texture is flexible and colorful, and it can be stretched freely to completely break the limitations of traditional smallpox in terms of shape, color, and small block assembly. At the same time, it has excellent features such as fire prevention, bacteria prevention, waterproof, energy saving, environmental protection, anti-aging, and easy installation.

The film is a material that can change its shape at will. The design of the steel frame keel is used to determine shape of tension fabric ceiling . Therefore, the shapes are random and diverse, which produces unexpected and strange effects, giving the designers & architects a wider creative space. Its modeling ability is unmatched by other smallpox materials. What's even more impressive is the change of color, the soft film ceiling is evenly colored, the smooth mask is as smooth as satin, has a strong light feeling, and has a mirror-like reflection effect.

Very suitable for interior ceiling & roof decoration of large and large space buildings. For example: large casinos, hotels, museums, exhibition halls, hospitals, gymnasiums, indoor swimming pools, spas and so on.

Advantages of the Custom Outdoor Shades Tensile Roofs in Argentina

March 06,2020

The Republic of Argentina is a presidential federal republic in the south of South America. body. Argentina is one of the developing countries with comprehensive national strength in the world. Argentina is also one of the world's major producers and exporters of food and meat.Advantages of the membrane tensile structure in Argentina as follow.

1. Economy

The cost of a roof structure design is only 1/3 to 1/2 of the cost of a traditional building. The cost of a tensile structure varies greatly according to different spans and design schemes, but the price-benefit ratio is very obvious compared to traditional construction .At the same time, because the film has a certain light transmittance, it can reduce the lighting intensity and time during the day, which can save energy well, and the gorgeous landscape formed by the transmission of colored lights at night can also achieve a good advertising effect.

All the processing and production in the membrane structure building project are completed in the factory, which can reduce the construction time on site and avoid construction crossover.

Compared with the traditional construction method, the construction period of the membrane structure building can be shortened by at least half, and the general project can be completed within two months, and the construction progress of other projects will not be affected during the construction period.

The membrane material used in the outdoor shade structures is very light, weighing only about 1 kg per square meter, so the membrane structure can fundamentally overcome the difficulties encountered in the implementation of traditional structures in large-span (unsupported) buildings, and can create The open and unobstructed visible space effectively increases the space usage area.

At present, the span of membrane structure buildings has exceeded 200 meters.

It presents changeable, novel and seductive visual effects, and its application range is not limited to sports or exhibition buildings, but also extends to houses and landscape architecture.

The scale of the tensile structure project can be large or small, including street sketches, waiting halls, and stadiums; the life span can be long or short, can be temporary tents, or long-term buildings of more than 30 years; colors can be used, flowers can be used, and film materials It can be dyed in a variety of colors like cloth, especially the translucent properties of the film material, which makes the film building in the night sky show a dreamy color under the light.

Tensioned fabric buildings uses membrane material with protective coating, so it has a good self-cleaning effect. It can use the natural scouring of rainwater to clean the appearance of the building, and also ensure the service life of the building.

In addition, the membrane structure also has the advantages of easy transportation, easy renewal and snow accumulation.

How to Clean & Maintain the Membrane Structure Carport?

March 03,2020

If the Tensile membrane structure carport has been used for several years, how to remove the dust on the fabric shade surface?

The fabric of tension membrane structure has a good cleaning function, but due to the influence of external factors will eventually cause dirt accumulation. For example: air pollution, deciduous bird waste, precipitation etc. From a technical perspective, the fabric structure car parking shade does not need to be cleaned. However, from an aesthetic point of view, regular cleaning of the membrane structure carport cloth can maintain the beauty of the membrane structure.

1. The membrane structure carport should be regularly cleaned with a cleaning agent. The membrane structure carport will be coated with a coating material for the surface treatment layer. When cleaning, pay attention not to use some cleaning agents, strong solvents, hard brushes and other cleaning agents and methods for cleaning. In this way, not only the cleaning effect is not achieved, but also the life of the membrane surface of the membrane structure shade may be affected.

2. The cleaning frequency must be combined with the actual situation. The cleaning membrane structure parking shed is generally combined with normal maintenance. Therefore, under normal circumstances, it is necessary to routinely check the equipment to ensure that the membrane structure is stably combined. 1-2 regular inspections and maintenance are performed every year.

3. Membrane structure carport For special environments, some membrane structure parking sheds need to be cleaned and maintained. Before the rainy season and rainy winter, the membrane surface should be inspected and cleaned up. The membrane surface drainage system should be normal to prevent the occurrence of standing water. Clear water or snow in time. If rain and snow continue, the accumulated water will cause damage to the membrane.

Archives

News at BDiR

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

March 27,2025

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

March 10,2025

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

March 04,2025

Watch Our Videos

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel

Luxury Sustainable Hospitality Eco Tent Structure Villas