Fabric Processing Factory

The membrane processing factory covers an area of 5,000 m2, with an annual production capacity of 200,000 m2 of PTEF; an annual production capacity of 100,000 m2 of ETFE; and an annual production capacity of 300,000 m2 of PVC / PVDF. We have the qualification of membrane structure design and construction issued by industry associations.

-

Purchase membrane

-

Material inspection

-

Membrane Cutting

-

Fabric Coating Polishing

-

Pre-positioning

-

Membrane Welding

-

Accessory assembly

-

Fabric Packing

-

Shipping & Delivery

-

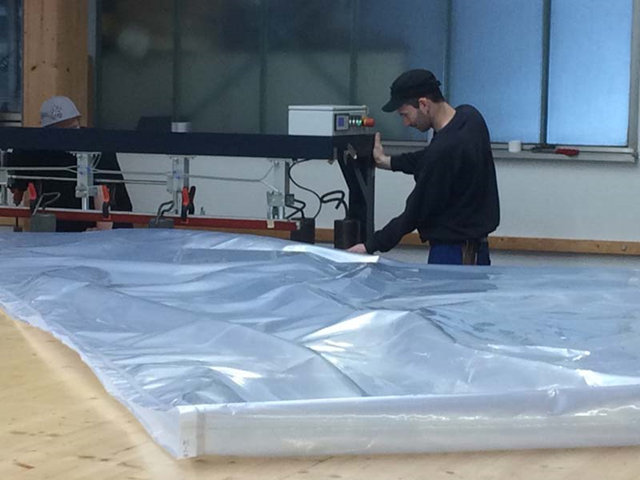

PVDF/PVC Welding Machine

Orbital PVC fabric high-frequency heat sealing machine. The PVC heat sealing platform is up to 20 meters long. The time for heat sealing and cooling can be adjusted according to the different PVC membrane material. The voltage can also be tuned with different Brand PVC materials to achieve the best results.

-

ETFE Fabric Welding

The automatic roller continuous welding machine: welding the two edges of ETFE film togethe, achieve strong tear strength while maintaining physical propertiesr. The welding effect is guaranteed to be firm and beautiful. The ETFE Welding machine is easy to operate, convenient to control.

-

PTFE Welding Machine

PTFE membrane heat sealing machine - this set of equipment is a pneumatic PTFE membrane heat sealing machine, the heat sealing temperature is up to 500 °C, mainly for the PTFE material film heat sealing. The temperature can be adjusted to the best heat sealing effect for different brand PTFE.

-

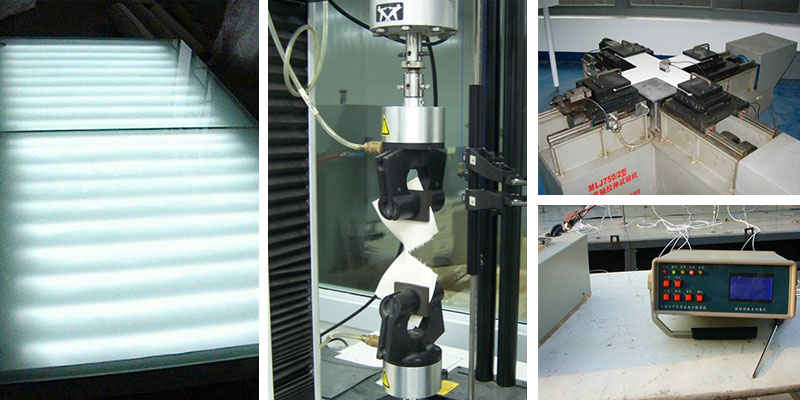

Testing Machine

Fabric optical inspection machine, use: film inspection, length inspection width 5 meters;Biaxial stretching machine, use: film strength test,stretching stroke 0-700mm test force measurement range 50N-10KN;Single-axis stretching machine, use: stress strain test, used to determine fabric scaling.