PVC Membrane Materials Commonly Used in Contemporary Architecture

November 10,2019

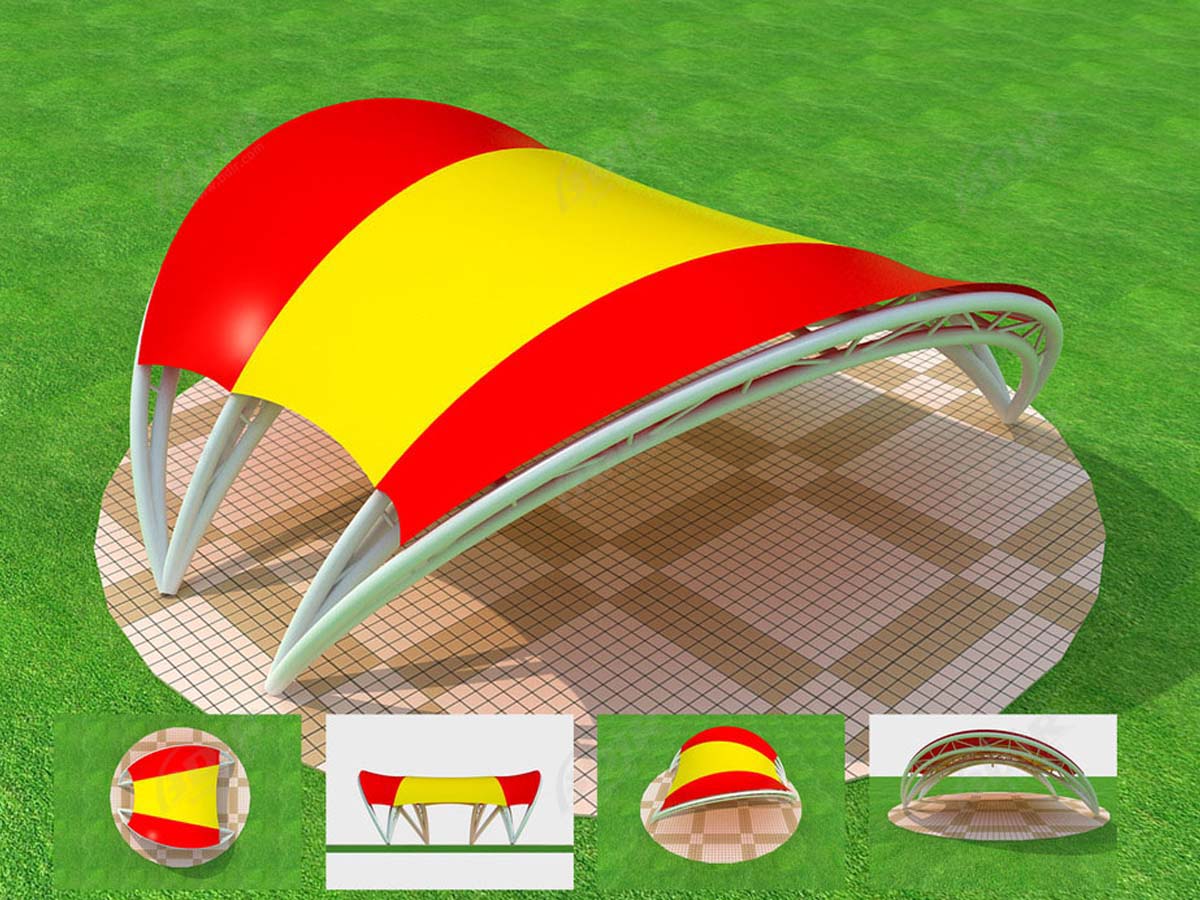

PVC membrane is the most common architectural membrane in our daily life. It is widely used in parking sheds, gas station ceilings, high-speed entrance and exit canopies, stadium ceilings, swimming pool awnings, outdoor landscape sheds, sports stands and canopies. PVC film is coated with polyester fabric as the substrate. In order to solve the problem of self-cleaning of PVC film, PVDF (polyvinylidene fluoride), or PVDF film, is usually applied on the PVC coating. At present, the most common architectural membrane used in domestic membrane structures is PVDF membrane. PVDF membranes can withstand various weather changes, and have excellent UV protection, excellent tensile properties and tear strength, and a wide range of light transmission options. In addition, PVDF membranes are available in a variety of colors to create a colorful and chic architectural look.

The following is a detailed description of the most commonly used white 1100g/m2 PVDF membranes from BDiR Inc., which is the most commonly used in the domestic market:

Project Unit Technical Data Technical Data Executive Standard Product Standard

Base fabric fiber / ultra low shrinkage high strength polyester filament DIN EN 60001

Yarn weaving dtex 1300D*1300D DIN ISO 2060

Woven yarn density (warp/weft) Threads/inch 32/34 DIN EN 1049-1

Weaving method / 2/2 Panama /

Base fabric weight g/m2 370 DIN EN ISO 2286-2

Gram weight g/m2 1100 DIN EN ISO 2286-2

Thickness mm 0.85±0.02 DIN EN ISO 2286-2

Tensile strength N/5cm 5500/5200 DIN EN ISO 1421

Tear strength N 600/550 DIN 53363 (Peak Method)

Peel strength N/5cm >120 DIN 53357

Applicable temperature °C (-40)~(+70) DIN 53363

Light transmittance % 6-8 /

Surface treatment / PVDF bright white coating, anti-wicking treatment /

Fire rating / B1 DIN4102-B1- GB8624-B1

Production standard / DIN EN ISO 9001, GB/T24001

The above data is test data according to relevant standards, only for reference

You can notice that there is an “anti-wicking treatment” in the surface treatment in the above table. What effect can anti-wicking treatment play? In the process of using the film, in order to make a variety of architectural effects, it must be cut and spliced. The splicing seam and the bare base fabric on the outside are affected by the humid climate such as rain. The "light absorbing effect" will cause the base fabric to absorb moisture and gradually wet until it penetrates the entire membrane base fabric, which will eventually lead to contamination of the surface of the membrane. At the same time, it will also reduce the performance and life of the membrane. At present, the domestic low-end building membranes have not been subjected to anti-wicking treatment, and the price of such membranes is relatively low. BDiR Inc. Xiaobian reminds everyone to pay attention to this when purchasing membranes, if there is no anti-wicking The treated membranes are recommended to try not to purchase.

Hot Search:

Previous: The Perfect Blend of Tensioned Structure and Lighting Art

Next: What is the Performance of PVC Spherical Geodeosic Dome Tent Material?

News at BDiR

Foshan Century Lotus Sports Center: A Masterpiece of Membrane Roof Design

December 21,2024

Tensile Fabric Structure Installation: Considerations for Installing Tensile Membrane

December 13,2024

What is a Tensile Fabric Structure? Why Load Analysis is Essential

December 07,2024

Watch Our Videos

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel

Luxury Sustainable Hospitality Eco Tent Structure Villas