RELATED PRODUCTS

Printed Silver Patterns ETFE Fluoropolymer Foils Air Pillow for Commercial Covers, Stadium Roof

Printed Silver Patterns ETFE Fluoropolymer Foils Air Pillow for Commercial Covers, Stadium Roof

950gsm PVF Architectural Shelter Fabrics for Beach, Seaside Shade Sail & Canopy

950gsm PVF Architectural Shelter Fabrics for Beach, Seaside Shade Sail & Canopy

1100gsm PVDF-coated Fabrics & Textiles Material for Tensile Shade Structure

1100gsm PVDF-coated Fabrics & Textiles Material for Tensile Shade Structure

Transparent ETFE Film Membrane Material for Commercial Facade & Roof

Transparent ETFE Film Membrane Material for Commercial Facade & Roof

News at BDiR

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

Geodesic Domes and Yoga: Creating the Perfect Space for the Mind and Body

Geodesic Domes and Yoga: Creating the Perfect Space for the Mind and Body

.png) Innovative Roof Designs for Stadium

Innovative Roof Designs for Stadium

Description

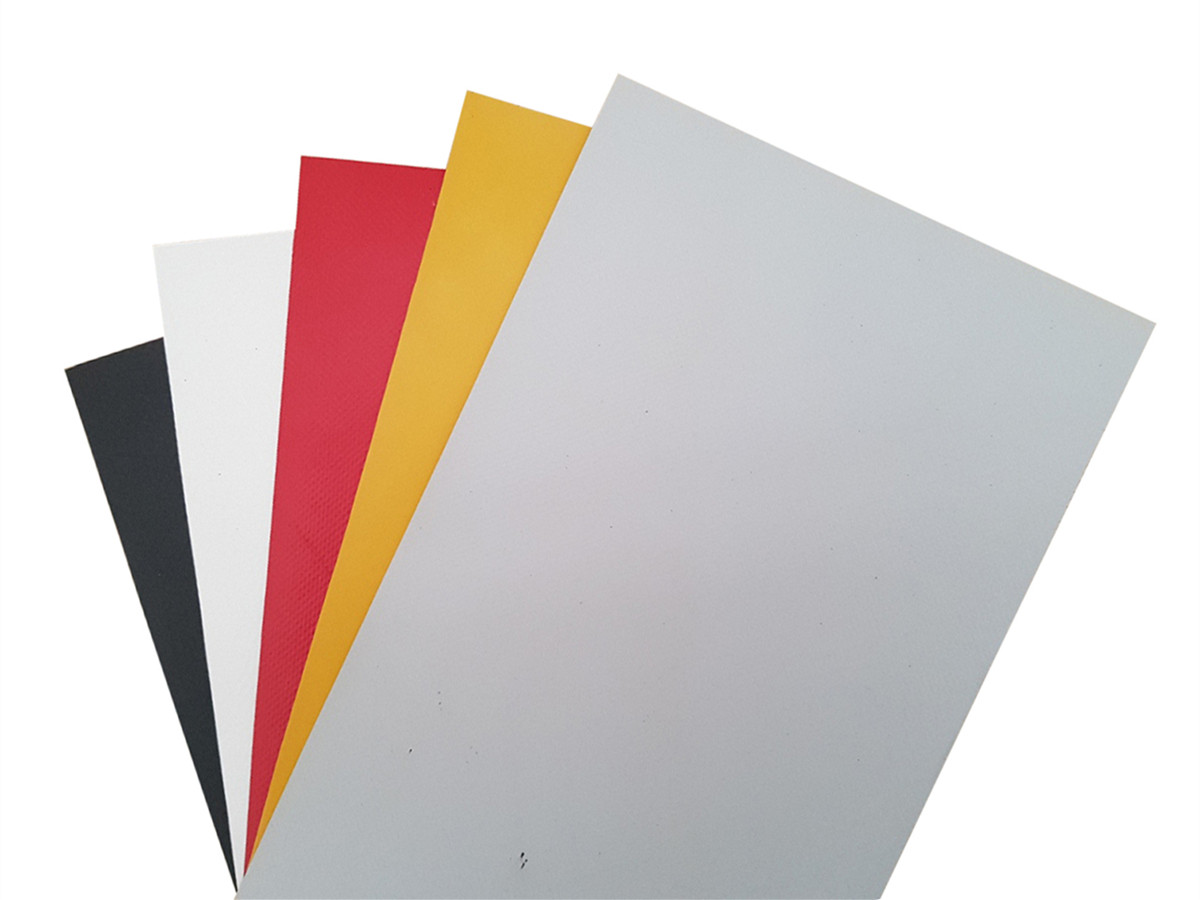

PVDF fabric material is a composite material formed by coating PVC (polyvinyl chloride) resin on polyester fiber base cloth and spraying PVDF (polyvinylidene fluoride) surface coating. The fabric substrate has tensile strength, tear strength, heat resistance, durability, and fire resistance. The coating material has weather resistance, antifouling properties, water resistance, and light transmittance.

PVDF membrane materials are widely used in various construction fields because of their good self-cleaning properties, moderate prices, and convenient transportation and installation. Its life span varies with different surface coatings, and can generally reach 10-25 years.

The surface of the PVDF membrane material is extremely important. The quality of the surface treatment not only affects the self-cleaning performance of the membrane material, but also affects the service life of the membrane material, anti-mildew and anti-ultraviolet properties. There are currently two common surface treatment methods for PVDF membranes on the market: weldable PVDF and non-weldable PVDF. Weldable PVDF membrane material has a low surface PVDF coating concentration, and the membrane material has almost no self-cleaning property, but the price is very cheap; non-welderable PVDF membrane material has a high surface PVDF coating concentration, which cannot be directly welded, and the processing is complicated. However, the surface of the membrane material has obvious self-cleaning properties, but the price is relatively more expensive than the weldable membrane material.

PVDF membrane materials are widely used because of their high cost performance and performance to meet the design requirements.

Application range of exterior wall membrane structure:

1. Sports facilities: stadium / gymnasium / tennis court / swimming pool / training center / fitness center, etc .;

2. Commercial facilities: shopping mall / amusement center / hotel / restaurant / commercial street, etc .;

3. Cultural facilities: exhibition center / theatre / performance center / aquarium, etc .;

4. Transportation facilities: airport / train station / pier / parking lot / overpass / gas station / toll station, etc .;

5. Landscape facilities: iconic sketches / square signs / community landscapes / pedestrian streets, etc .;

6. Industrial facilities: factories / warehouses / sewage treatment centers / logistics centers / greenhouses, etc.

Specifications

-

Detailed Specifications & Datas Sheet:

Items

Unit

Technical Data

Product Standard

Base Fabric

-

Polyester

DIN EN 60001

Yarn Count

Dtex

1000*1000

DIN ISO 2060

Type of Coating

-

PVC

-

Surface Treatment

-

Self-cleaning PVDF

-

Total Weight

g/m2

950

DIN EN ISO 2286-2

Thickness

mm

0.75±0.2

DIN EN ISO 2286-2

No.of Threads

Threads/inch

30*32

DIN EN 1049-2

Tensile Strength

N/5cm

4200/3800

DIN EN ISO 1421

Tear Strength

N

500/450

DIN 53363 (Peak Method)

Adhesion

N/5cm

≥120

DIN 53357

Threshold Temperature

℃

(-30)~(+70)

ASTM D1790-08

Translucency

%

6-8

-

Flame Retardancy

-

B1

DIN4102-B1, GB8624-B1

Other Functions

-

Anti-UV, Anti-fungal,Mildew proof

-

*Standard width: 3m (Customizable), Roll length: 100m, Area: 300m2

Design & Model

Fabric Cutting Analysis & Design Services

Fabric Inspection & Cutting & Welding Services