Hot Search: tension structures, tensioned structures, tensioned structure, tension in structures, roof membrane, sustainable architecture, green architecture, modular buildings, tensile structure, tensile structures, tensil structures, tensil structure, shade structures, roof structure, roof structures, structure of roof, fabric shades, shade structure, pvdf membrane, canopy roof,

RELATED PROJECTS

News at BDiR

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

Geodesic Domes and Yoga: Creating the Perfect Space for the Mind and Body

Geodesic Domes and Yoga: Creating the Perfect Space for the Mind and Body

.png) Innovative Roof Designs for Stadium

Innovative Roof Designs for Stadium

Description

In November 2024, BDiR completed the installation of a 1,550-square-meter tensile membrane shading canopy for the tennis court at China Mobile in Guangzhou.

The canopy features a dynamic wave-shaped design, specifically adapted to the region's tropical climate and seismic conditions. A robust concrete foundation guarantees long-term stability, providing a solid base for the structure to withstand the elements.

This shading solution offers multiple benefits. It's cost-effective, easy to install, and protects the tennis court from water accumulation, UV rays, fungal growth, and side winds. With a 5% transparency rate, it also contributes to energy savings. The installation process was impressively completed in just 15 days by a dedicated team of 10 workers.

Selecting the appropriate membrane material was essential. For coastal regions like Guangzhou, high tensile strength and wind resistance were prioritized. Meanwhile, in Southeast Asia, UV-resistant fabrics were favored to withstand the intense sun exposure. In northern regions, the focus shifts to materials that provide thermal insulation and are capable of withstanding heavy snow loads.

Specifications

√. Large Span: Tensile Structures can create an expansive covered area, exceed to 200m.

√. Unique Design: Tensile fabric Structure gives architects, designers, and engineers the opportunity to experiment with form and create visually exciting and iconic structures.

√. Various Shape: Changeful supporting structure can make lots of different shapes of tensioned structure with flexible membrane.

√. Cost-effective: About 1/3 to 1/2 lower than conventional structures on costs.

√. Easy to Install: Faster and more cost-effective in comparison to traditional construction projects.

√. Weatherproof: Durable and designed to withstand even the most severe weather conditions. Provide protection from both the rain and sun.

√. Excellent Durability: Fabric tensile Structure is characterized by durability and longevity, can be built in different areas around the world, from the frigid arctic pole to the scorching desert heat.

√. ECO Friendly: Have high sun reflectivity and low solar absorption. As a result, less energy is used in the building, ultimately reducing the cost of electricity.

√. Low maintenance Needs: Tensile membrane Structures require minimal maintenance for clients, whether use of PVC, PVDF, PTFE or ETFE.

√. Outstanding Natural Daylighting: Membrane is translucent, In daylight, tension structures could offer rich soft diffused naturally daylight space, and at night, artificial lighting can make it bright and colorful.

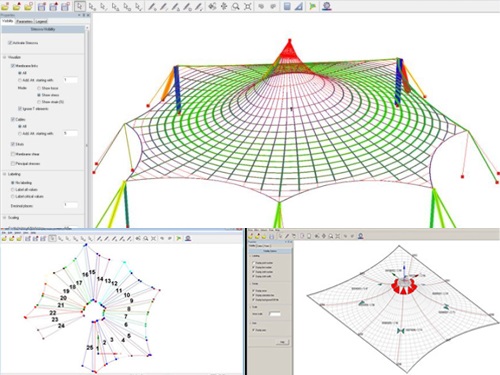

Design & Model

Installation

|

|

Step 1: Design |

|

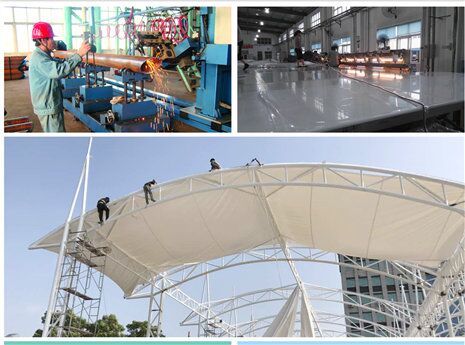

Step 2: Membrane Fabrication |

|

|

|

Step 3. Steel Fabrication |

|

Step 4: Cable Fabrication |

|

|

|

Step 5: Installation |

|

Step 6: The Future |

|

.png)

.png)

.png)

.png)

.png)

.png)