BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

March 04,2025

BDIR specializes in cutting-edge stage membrane structures that transform events into unforgettable experiences. Designed for global clients, our solutions blend architectural elegance with engineering precision, creating iconic spaces for concerts, exhibitions, festivals, and corporate events.

-

Sleek & Functional Design: Customizable shapes and sizes to match any theme or branding.

-

Durable Materials: High-performance PVC or PTFE membranes ensure weather resistance, UV protection, and long-term reliability.

-

Rapid Installation: Engineered for quick setup and dismantling, ideal for time-sensitive events.

-

Sustainability: Eco-friendly materials and energy-efficient designs align with modern green standards.

Global Applications

From open-air music festivals in Europe to luxury product launches in the Middle East, BDIR structures adapt seamlessly to diverse climates and cultural needs. Our projects have elevated events worldwide, offering both visual impact and practical functionality.

Partner with BDIR

Elevate your next event with a stage that captivates. Contact BDIR to explore bespoke membrane structure solutions tailored to your vision.

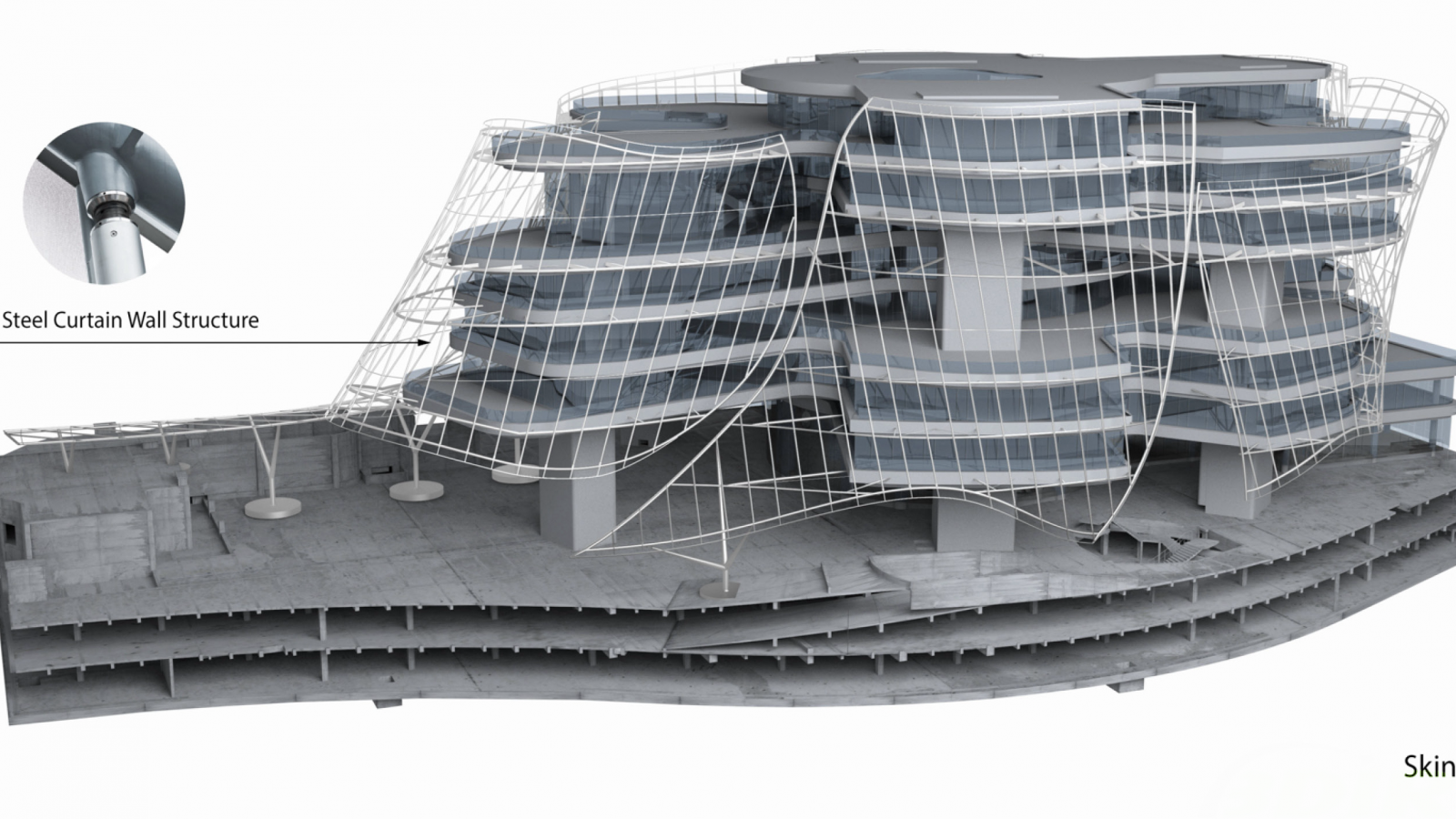

Innovative Roof Designs for Stadium

January 13,2025

.png)

The Guangzhou University Central Stadium, accommodating 40,000 spectators with a 33,673 m² area, showcases unique roof designs tailored to its landscape. Designed for a basic wind pressure of 0.6 Kpa (112 km/h wind speed), the east and west stands feature distinct structures.

The east stand is integrated into the hillside, with the architect’s concept of merging the stand into the mountain, creating a part of the hill. A green artificial turf-covered sandwich panel roof extends over the stadium, seamlessly blending with the landscape. The roof is supported by a suspension structure, transferring loads efficiently to the foundation.

.png)

The east stand, merging with a hillside, has a green artificial turf-covered sandwich panel roof (9500 m², 257 m span, 34 m cantilever). Using a suspension structure, it efficiently transfers load to the foundation.

.png)

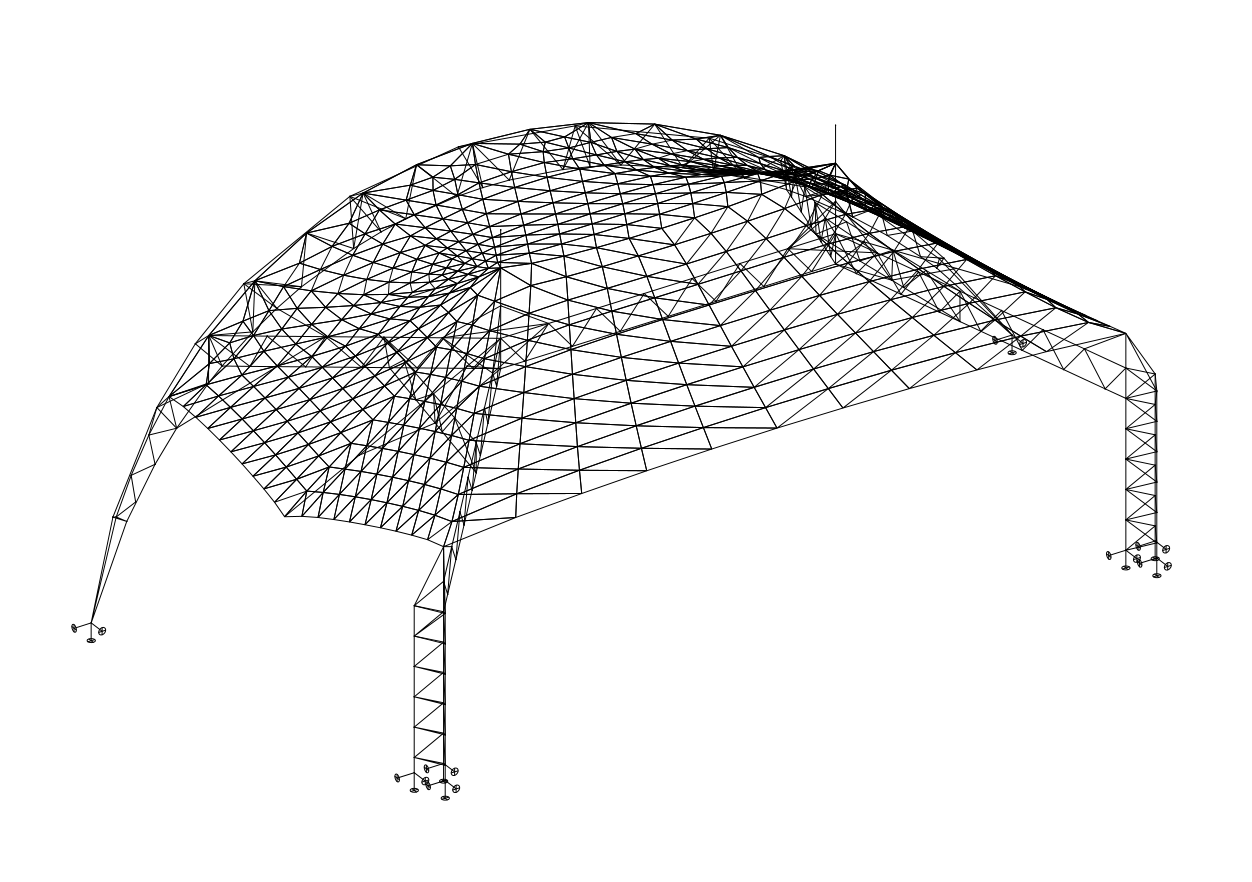

The west stand symbolizes "clouds over mountains" with a PTFE membrane roof (16,000 m², 300 m span, 60 m cantilever), supported by radial and circular trusses.

.png)

.png)

Efficient, Aesthetic, Sustainable, and Cost-Effective: The Future of Membrane Facades

December 27,2024

Membrane materials have increasingly been used for building facades, offering a range of benefits such as fast installation, low construction costs, and effective surface coverage that enhances both aesthetics and signage. As a result, mesh membrane materials are commonly found in commercial centers, cultural hubs, exhibition halls, and sports venues.

One popular option is the use of perforated mesh membrane, which features a wider spacing between base fibers and a partial coating, resulting in a certain perforation rate (20–70%). This material has high transparency (30-70%), allowing natural light to penetrate while maintaining excellent shading and decorative effects. Alternatively, semi-transparent membranes can be used for different applications, offering a balance of light diffusion and energy efficiency.

Project Case 1: Germany Pavilion at Expo 2010, Shanghai

The Germany Pavilion at the 2010 Shanghai Expo covered an area of 6,000 m². The facade was constructed using high-strength PTFE membrane with a Ferrari metal silver coating and 28% perforation. Approximately 21,000 m² of membrane material was stretched over the pavilion’s roof and surrounding walls. This membrane effectively blocked up to 80% of sunlight radiation, significantly reducing the building’s cooling load while allowing natural light to enter. As a result, the pavilion's energy efficiency was greatly improved.

Project Case 2: Germany Pavilion at Expo 2015, Milan

At the Milan Expo 2015, the Germany Pavilion also utilized membrane structures as a key material in its design. This highlighted the growing recognition and use of flexible textile technology in architectural design, demonstrating its adaptability and sustainability for global expos.

Project Case 3: Xinhe R&D Design Center

The Xinhe R&D Design Center, with a total building area of 61,000 m², features a semi-transparent membrane facade that allows 40% of light to pass through. The PTFE membrane is installed at a distance from the building, reducing sunlight intensity and providing ventilation during hot seasons, while still allowing for natural light inside. This innovative facade design ensures both energy efficiency and comfort for office spaces.

Foshan Century Lotus Sports Center: A Masterpiece of Membrane Roof Design

December 21,2024

The Foshan Century Lotus Sports Center, located in Foshan New City, Guangdong Province, was built for the 12th Guangdong Provincial Games and has become a landmark of the city. The center, designed by the German firm GMP, covers 42 hectares and includes a stadium and a swimming and diving hall. The stadium, named "Century Lotus" for its lotus-shaped design, features a membrane roof that is both striking and functional.

The roof, which was completed in 2006, spans 310 meters in diameter and is made of PVDF membrane material. The structure includes a double-ring design: an inner tensile ring made of steel cables and an outer compression ring supported by concrete-filled steel pipes. The roof is designed to withstand the high humidity and tropical climate of Foshan, which is characterized by hot and damp conditions. The membrane's excellent durability and UV resistance are essential for enduring the region's challenging weather, with wind speeds reaching up to 28m/s.

The membrane structure not only provides superior environmental resistance but also adds to the aesthetic appeal of the stadium, making it a recognizable symbol in Foshan. The roof's unique design allows for easy maintenance while offering optimal protection from the elements, contributing to the stadium’s long-lasting functionality and iconic status.

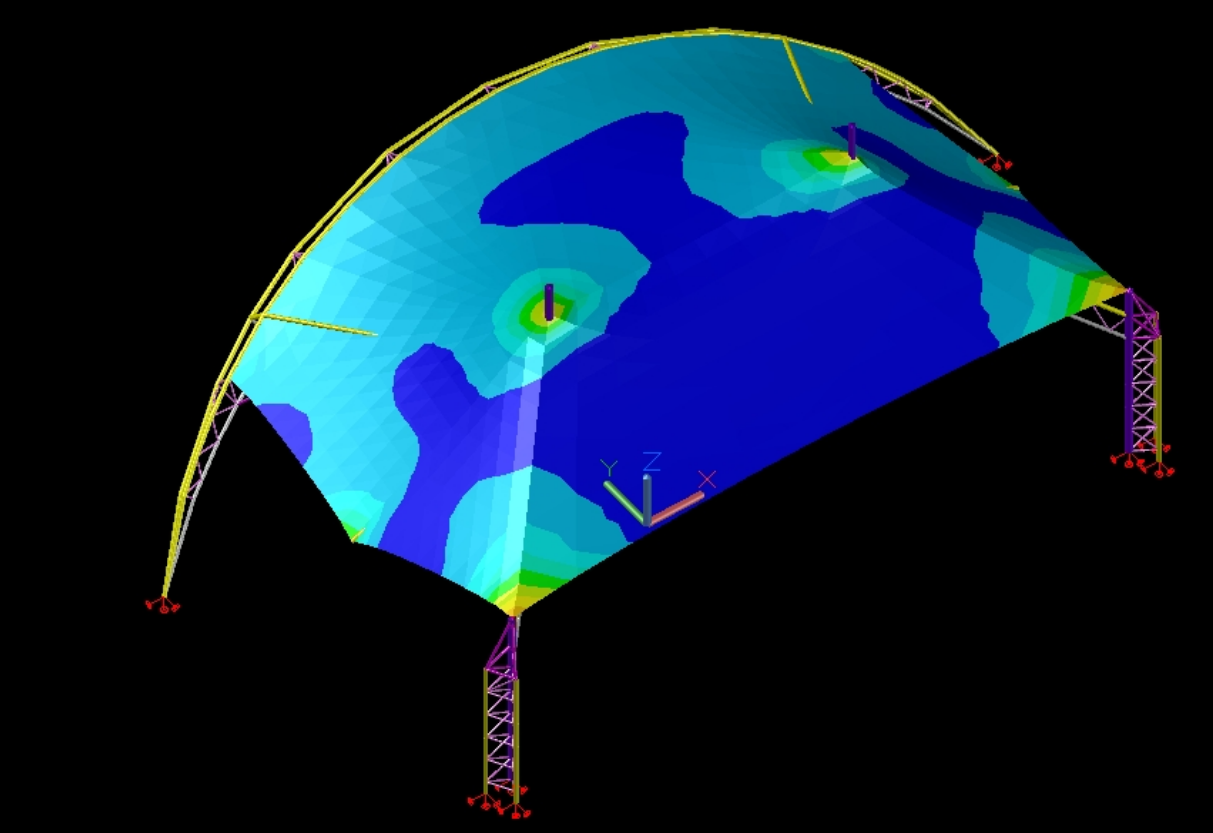

What is a Tensile Fabric Structure? Why Load Analysis is Essential

December 07,2024

A tensile fabric structure is a lightweight architectural solution that relies on the balance of tension and compression. Unlike traditional buildings, it uses fabric materials like PVC, PTFE, and ETFE, supported by cables and steel frames, to create elegant, durable, and cost-effective shelters. These structures are widely used in stadiums, canopies, exhibition halls, and shade structures due to their unique aesthetic appeal and functional flexibility.

To ensure the stability and safety of these structures, load analysis is essential. This analysis evaluates the forces acting on the structure, such as wind load, snow load, live load, and temperature load, to prevent issues like sagging, tearing, or collapse.

Wind Load: Wind creates pressure that can push, pull, or lift the fabric. Proper design reduces wind resistance by shaping the fabric to deflect airflow. BDiR uses advanced software to simulate wind forces and ensure the stability of the structure.

Snow Load: In colder regions, snow accumulation can increase weight on the roof, leading to sagging or collapse. Proper slope design ensures snow slides off, while fabric tensioning increases load capacity.

Live Load: This refers to temporary loads like maintenance workers walking on the structure or hanging decorative items. Load capacity is built into the design to ensure the structure remains stable under such loads.

Temperature Load: Temperature changes cause fabric and metal components to expand or contract. BDiR selects materials with high thermal resistance and designs tension systems to adapt to these shifts, ensuring long-term stability.

Load Calculation: BDiR's engineers collect environmental data (wind speed, snow density, temperature) and apply load coefficients. Advanced software simulates forces, and adjustments are made to the fabric shape, pre-tension, and anchor points.

Custom Design: Each project is tailored to the site's unique climate conditions. BDiR’s designs feature optimal slope, fabric curvature, and reinforced anchor points to resist wind, snow, and live loads.

Material Selection: Using materials like PVDF and PTFE, BDiR ensures resistance to UV, weather, and thermal expansion.

Pre-Tensioning: The fabric is stretched to the correct tension before installation, preventing sagging and ensuring a taut, smooth surface that resists external forces.

BDiR offers custom design, load analysis, and premium materials to deliver durable and aesthetically appealing tensile fabric structures. Our team ensures that every project is tailored to local climate conditions, with a focus on wind load, snow load, and live load stability. With experience in stadiums, exhibition halls, and large public canopies, BDiR is your trusted partner for safe, durable, and elegant tensile structures.

BDiR offers custom design, load analysis, and premium materials to deliver durable and aesthetically appealing tensile fabric structures. Our team ensures that every project is tailored to local climate conditions, with a focus on wind load, snow load, and live load stability. With experience in stadiums, exhibition halls, and large public canopies, BDiR is your trusted partner for safe, durable, and elegant tensile structures.

If you're planning a tensile fabric structure project, contact BDiR for professional load analysis and custom design services.

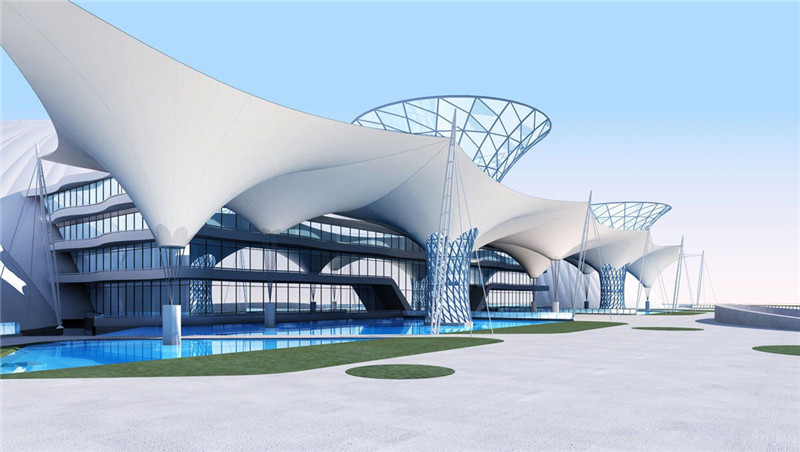

Tensile Membrane Structures: Innovation, Aesthetics, and Performance

November 29,2024

Tensile Membrane Structure: The Perfect Combination of Innovation and Aesthetics

Tensile membrane structure is an innovative architectural form that uses high-strength flexible membrane materials combined with auxiliary structures to create a stable space through pre-tension. It breaks the framework of traditional architecture with its unique curvilinear beauty and exceptional mechanical performance. Since its development in the mid-20th century, tensile membrane structure has been widely applied in modern architecture, especially in large public buildings, sports facilities, commercial centers, and exhibition halls.

Why Choose Tensile Membrane Structure?

Tensile membrane structure not only meets the need for large-span spaces but also creates a unique architectural charm through its distinctive design language. Whether it’s innovative shapes, fast construction, or outstanding durability, tensile membrane structures have secured an important place in the architectural world. Below are the key advantages:

1. Lightweight and High Strength: The Ideal Choice for Large Spans

The membrane materials used in tensile structures are not only lightweight but also strong enough to cover large spans, significantly reducing the weight of the building. This gives tensile structures a clear advantage in scenarios that require large-area coverage and free-form design. Whether it’s a sports stadium, exhibition center, or shopping mall, tensile membrane structures offer flexible space solutions.

2. Versatile Shapes: A Combination of Art and Function

The flexible nature of membrane materials allows for the creation of various unique shapes, from streamlined curves to complex geometries, enabling architects to freely explore creative designs. Its beautiful curves not only possess strong aesthetic appeal but also blend perfectly with the surrounding environment and architectural style, becoming an artistic highlight in the building.

.jpg)

3. Quick Construction: Efficient and Convenient Building Method

Compared to traditional construction, the construction cycle of tensile membrane structures is greatly shortened, and the installation process is simple and convenient. The membrane materials can be pre-fabricated in factories, and on-site, only the auxiliary structure needs to be fixed and tensioned, significantly reducing construction time and costs. For projects that need to be completed quickly, tensile membrane structures provide an effective solution.

4. Strong Durability: Adapting to Extreme Environments

High-quality membrane materials are specially treated to offer excellent weather resistance, protecting against ultraviolet rays, rain, and other natural factors. The durability of membrane structures has been proven in extreme climates worldwide, whether in deserts, coastal areas, or cold regions, tensile membrane structures maintain stable performance.

If you would like to learn more about tensile membrane structures or consult us on how we can provide customized solutions for your project, feel free to contact us at any time. We will offer you professional design and high-quality construction services to help you achieve your ideal architectural results.

How We Analyze Customer Needs and Projects Before Purchasing a Tensile Fabric Structure

October 30,2024

1. Initial Consultation

Discussion: We start with a detailed conversation to get a sense of your vision for the tensile structure. We want to understand not just the purpose but also the functional requirements that matter to you.

Questions: We’ll ask about how you plan to use the tensile fabric structure, where it will be located, and any specific preferences or constraints you might have.

2. Site Assessment

Information Provided: We ask clients to provide site information, such as photos and relevant drawings. This helps us assess the physical environment where the tensile structure will be installed, considering factors like terrain, climate, and surrounding architecture.

Measurements: Accurate measurements of the site are crucial. They help us identify space limitations and opportunities for your tensile structures.

3. Functional Requirements

Purpose: We’ll determine what you want the tensile structure to achieve—whether it’s providing shelter, serving as an aesthetic feature, or creating a recreational space.

Capacity: Understanding how many people you expect to accommodate helps us design a structure that fits your needs.

4. Design Preferences

Style: We’ll discuss your design preferences, including shapes, colors, and materials. Your input is vital to creating a tensile architecture that you love.

Inspiration: If you have any inspiration images or previous projects that resonate with you, we’d love to see them. They help guide the design process.

5. Technical Specifications

Load Requirements: We’ll calculate the structural load requirements for your tensile structures, factoring in wind, snow, and other environmental conditions. Safety is our top priority.

Materials: Let’s talk about material options for the fabric and supporting structure. We want to consider durability, aesthetics, and maintenance needs to ensure tensile fabric structure lasts.

6. Budget Constraints

Cost: Understanding client's budget is essential. We aim to propose design and material options that fit within the financial plan for the tensile fabric structure.

Flexibility: We’ll discuss whether there’s any flexibility in your budget for higher-quality materials or extra features that could enhance your structure.

7. Regulatory Compliance

Permits: We’ll make sure that your design complies with local building codes and regulations. It’s important to keep everything above board.

Standards: Adhering to industry standards for safety and durability is something we take seriously in our tensile architecture designs.

8. Timeline

Schedule: Establishing a clear timeline for the design, manufacturing, and installation phases is key to keeping everything on track.

Deadlines: We’ll discuss any critical deadlines or project milestones to ensure the tensile fabric structure is completed on time.

9. Review and Feedback

Proposals: We’ll present initial design concepts and proposals to you for feedback. Your thoughts are crucial in this stage.

Revisions: Based on your input, we’ll make any necessary revisions to finalize the design, ensuring that the tensile architecture perfectly meets your expectations.

10. Conclusion

By following these steps, we strive to understand your needs thoroughly and deliver a custom tensile fabric structure that aligns with your vision.

Gebruik en voordelen van trekconstructies

July 27,2022

Een trekconstructie is een lichtgewicht weefselstructuur die lasten draagt door gebruik te maken van spanning. Stretch Structures Fabric Structures beschrijft verschillende stretchfolie structuren en de huidige stand van kennis. Trekweefselstructuren worden vaak gebruikt in transportfaciliteiten, gebouwen en andere toepassingen die een hoge mate van duurzaamheid en esthetiek vereisen. Ze kunnen ook worden gebruikt als een lichtgewicht alternatief voor stalen frames, zoals wolkenkrabbers, schaduwstructuren voor speelplaatsen, tuinschaduwstructuren, enz.

Het ontwerp van trekconstructies kan variëren, afhankelijk van de behoeften van een specifiek project. Ze worden vaak gebruikt om schaduw of schaduw te bieden aan gebouwen. De schoonheid van trekstructuren maakt ze een aantrekkelijke optie voor vele soorten faciliteiten. Ze bieden ook een unieke combinatie van betrouwbare functionaliteit en esthetische aantrekkingskracht. Deze voordelen maken ze tot zeer populaire structurele systemen. Enkele voorbeelden van trekstructuren worden hieronder vermeld. Trekstructuren kunnen worden ontworpen met grote of kleine oppervlakken. Het kan grote ruimtes bedekken, zoals evenementenlocaties, stadions, podia voor optredens of militaire constructies. Kleinere voorbeelden zijn buitenrestaurants, rooftopbars, gespannen schaduwzeilen en meer. Trekconstructie is een uitstekende keuze voor buitentoepassingen omdat het een buitengevoel geeft en weerbestendig is. Door zijn unieke membraanspanningseigenschappen heeft de trekweefselstructuur een unieke elegante vorm. De doorschijnendheid zorgt ook voor zacht, diffuus natuurlijk licht. Kunstlicht kan ook worden gebruikt om buitenverlichting te genereren. Trekconstructies kunnen worden gebruikt om geprefabriceerde modulaire gebouwen te maken of als lichtgewicht elementen van bestaande constructies. Ze zijn een van de meest kosteneffectieve opties op de markt. Wanneer ze op de juiste manier zijn ontworpen en geconstrueerd, kunnen elastische weefselstructuren zeer duurzaam zijn.

.jpg)

De Duitse architect Frei Otto was een baanbrekende figuur in de ontwikkeling van trekarchitectuur. Het baanbrekende werk van Frei Otto toont aan dat de relatie tussen architecturale en structurele vorm intiem en wederzijds voordelig is. Het monumentale spangebouw van Frei Otto, de Hangende Dach in München, won in 2015 de Pritzker Architecture Prize. Het herdefinieert structuren en geprefabriceerde systemen en laat zien dat ze compatibel zijn met duurzaam ontwerp. Stretchstoffen zijn typisch combinaties van vezels die in verschillende toepassingen worden gebruikt. Trekstructuurdetails hebben veel voordelen, waaronder de mogelijkheid om het oppervlak tussen de punten te minimaliseren. Bovendien is het zeer efficiënt en maximaliseert het het gebruik van dure, zeer sterke vezels. En omdat het licht is, is het ook duurzaam. Als u op zoek bent naar trekconstructies voor uw project, neem dan vandaag nog contact met ons op!

Spanconstructies zijn kosteneffectiever en gebruiken minder materiaal dan spanweefselgebouwen. Trekstructuren kunnen hele gebouwen creëren, waardoor ze de eerste keuze zijn voor complexe ontwerpwerkzaamheden. elastische weefselstructuren zijn meestal gemaakt van dunne stoffen die in tegengestelde richtingen worden getrokken om een dubbele kromming te creëren. De dubbele kromming verdubbelt de stijfheid van de stof. Trekstructuren kunnen grote afstanden overbruggen zonder tussensteunen.

Archief

Nieuws bij BDiR

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

March 04,2025

Bekijk onze Video's

Luxe milieuvriendelijke tentstructuren Lodges voor Tea Garden Holiday Hotel

Luxe duurzame gastvrijheid Eco Tent Structure Villas