Why Should Us Choose Tension Fabric Structures Replace with Traditional Buildings?

November 10,2019

Tensile Structure Installation Steps

November 10,2019

About BDiR Inc.

October 12,2020

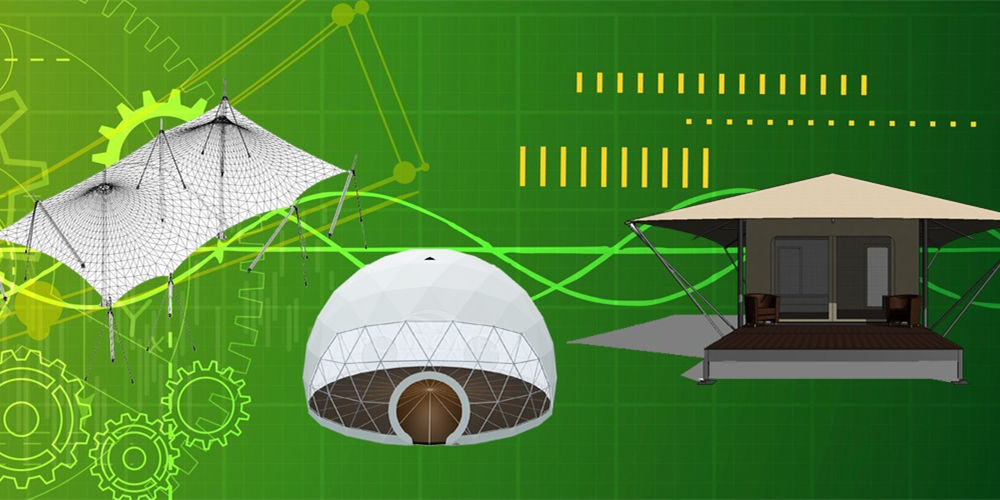

BDiR Inc. was established in 2008, located in Shenzhen, China. As the leading manufacturer, supplier, trader and wholesaler provider of Tensile Structures. We are engaged in offering a complete turn-key solution for all our customers needs. We offer design, installation, fabrication and maintenance services for all types of Tensile Structures.

With 10 years of experience in the tensile membrane structures industry, we have successfully designed, manufactured and installed thousands of high quality tension membrane construction projects in 37 countries around the world. We have 0 fault structure in our projects over the past 10 years. The tensile fabric structures used as roofing / canopy / shade / sail / marquee for sports facilities, transportation facilities, cultural facilities, landscape facilities, commercial facilities, sewage treatment canopy, biogas storage tanks, Air membranes structures, membrane structure hotels, Geodesic Domes etc. Our structure complies with local and international wind and snow load standards. We will never take risks when we provide our customers with a tensioned membrane structure that meets the wind and snow load requirements of each region or country.

We have a wide selection of standard tensile Fabric structure databases to offer you a choice. For customers looking for a more innovative custom design structure, we can design, engineer, manufacture and install custom stretch structures for you. We offer a full range of services from concept design to fabric structure project implementation.

If you have an idea you want realized, give us a buzz, you may be pleasantly surprised of what we can achieve.

Why Should Us Build a Car Parking Shade Tensile Structure?

November 10,2019

Why build a Car parking shed tensile structure? What is the production process of the parking shed? Here is the answer from BDiR: the reason for the construction of the Car parking shed tensile structure and the production process.

First, why should we build a Car parking shed tensile structure?

Then why do you want to live in the house? You think that the car has no life. Do you know that if the car is blowing in the sun and rain, will it be more than twice the original use period? It is like a car you originally used. It can be used for 10 years. There may be less than 3 years of use in the wind, the sun and the rain. Don't forget that the structure of the car is steel, and oxidative rust is inevitable, even if the advanced car is just the same. You can't see the naked eye inside, don't forget that the rain is acidic, it will speed up the erosion, the sun is also very scary, it will age, the wind is also the wind, it will erode, and the parking shed can not only Wind and rain, you can also block high-altitude parabolic!

Reasons for building a Car parking shed tensile structure and the production process

Second, what is the production process of the parking structure of the membrane structure?

So, how should it be divided into different categories is the decision to adopt the Shenzhen film structure carport production process? I think it can be started from the following aspects: First, the geographical location of the carport is accurate. The delineation of the carport is recognized as the promotion of the theme of the entire community environment. It is to properly handle the relationship with the property and land authorities. Second, it is necessary to proceed from the desire to build a harmonious community. After the coordination with other owners, it is necessary to further develop The construction plan; the third is to pay attention to the addition of membrane structural materials, play a supporting role of new material technology.

In the future, the material that is dominated by the information industry is a new era of application. It is a new idea to start energy saving and reduce emissions. It plays a powerful era of music and perfects the details of the programming platform. We pay attention to all aspects of the film structure carport production process, and we will get it in a longer period of time. Prepare the necessary information. Establishing a long-term mechanism of fair coordination and operational coordination requires us to further improve and improve with the help of existing platforms. When we humbly accept the suggestions of other owners of the community and put them into practice, it is the complete transformation of our Yunnan membrane structure carport. Time.

Building a harmonious community of environmental protection, economy, pragmatism and efficiency requires us to cut through the process of perfecting the membrane structure of the carport. It is an opportunity to seek to have an intrinsic affinity. It can be to further create the necessary conditions and search for those. The main material with special functions will go all out to build a compact and functional membrane structure carport as the ultimate project goal. When this vision is gradually implemented, it is achieved, and the quality of our own ability is that there is a great degree of leap.

Archief

Nieuws bij BDiR

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

March 04,2025

Bekijk onze Video's

Luxe milieuvriendelijke tentstructuren Lodges voor Tea Garden Holiday Hotel

Luxe duurzame gastvrijheid Eco Tent Structure Villas