360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

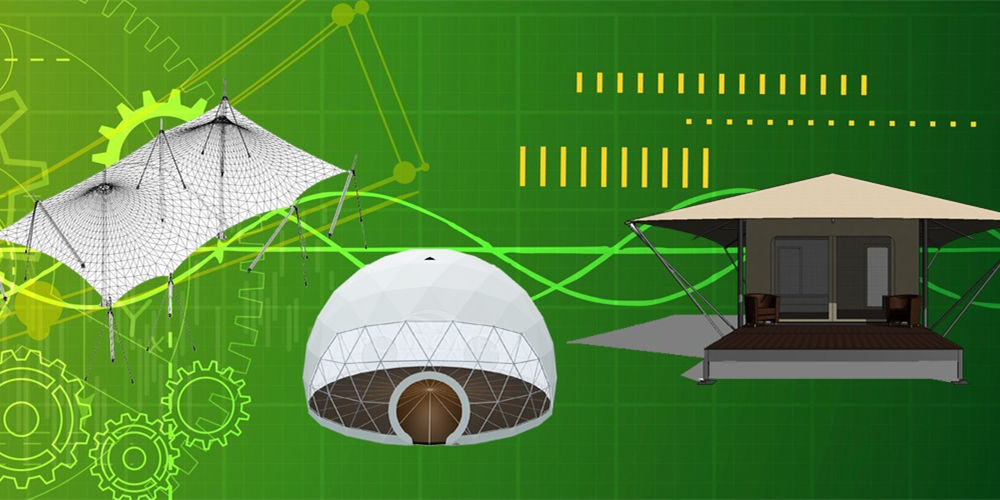

360° Projection Dome, also known as a planetarium dome or immersive dome, is a specialized projection surface, that creates an immersive environment by projecting images or videos onto the inner surface of a hemispherical or partially spherical dome. This creates a 360-degree view that surrounds the viewer, giving them the sensation of being completely immersed in the environment being projected. The surface can be either a flat or a curved projection screen, typically made of a high-gain material, and the projection is usually achieved by using multiple projectors or a single projector with a fisheye lens

360°Projection Domes tents are used for a variety of events and applications, including corporate events, music festivals, trade shows, entertainment, education, and scientific visualization. In entertainment, they are commonly used to create immersive experiences for visitors at theme parks, museums, and other attractions. In education, they are used as a tool to teach astronomy, geology, and other subjects that require a visual and immersive experience. In scientific visualization, they are used to display complex data sets and simulations. They can vary in size and shape, ranging from small tents that can accommodate a few people to large tents that can hold hundreds or even thousands of attendees.3D Projection Tent offers a unique and immersive way to experience content and can create a memorable experience for attendees of events or exhibitions. They are typically equipped with powerful sound systems and can be controlled by a computer to synchronize the visuals with the audio. 360° Projection Domes provide a unique and immersive way to experience content, enabling users to feel fully immersed in the environment being projected around them. the uses of 360° projection dome tents are diverse and varied, and they are becoming increasingly popular as a way to create immersive and engaging experiences for a wide range of applications

360° Projection Domes is designed to give everyone the best seat in the house! Through the magic of geodesic engineering and the medium of Immersion Technology along with projection mapping, portable 360⁰ Projection Domes create a rich environment for the benefit and enjoyment of all audiences.360° projection tent domes for outdoor theaters and planetariums play a key role in the future of interactive entertainment and education, inviting live audiences to make deeper connections with the world around them through dynamic group energy. The educational show, planetarium, museography, learning experience, and our immersive domes offer a large space for a total immersion extremely rich in emotions for all subjects and all ages. By combining video mapping, sound, and light, we guarantee that your audience will be impressed! The open space of the dome theater provides the perfect spatial entertainment and educational platform for shared human interactions. Explore new worlds with the immersive virtual reality experience

Fulldome projection is a combination of spherical tent design and interior decoration. Using the advantages of its own curved surface design, various elements such as light, audio and video are fused and released. In order to improve the application value of the inflatable projection dome, and thus create a more flexible space, in the future, the internal projection mode of the dome tent will be better promoted and applied with the development of technology

360° projection dome can accommodate a large number of people, which makes it ideal for events and other public installations. The dome can be constructed to be very large, which allows for a large number of people to experience the content simultaneously.

.jpg)

.jpg)

.jpg)

.jpg)