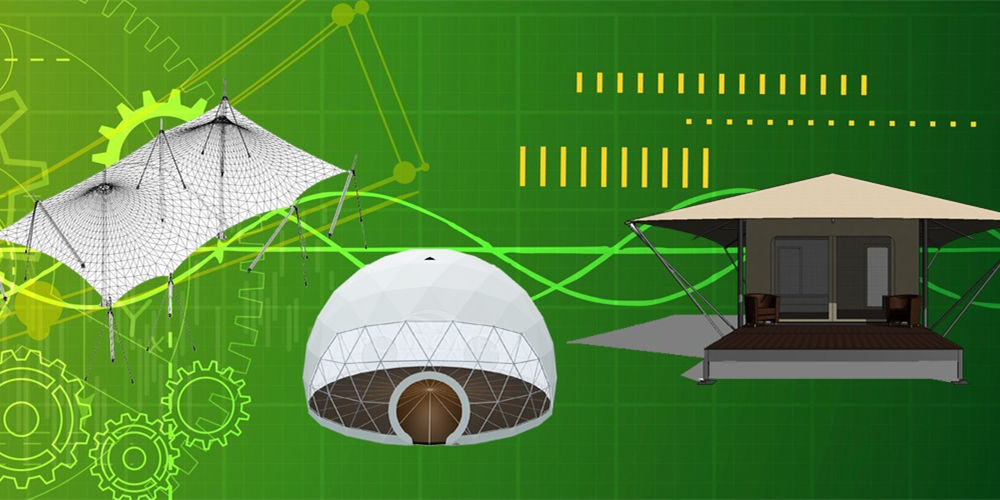

Diseño y Fabricante Profesional de Estructuras de Membrana Extensible

Con 10 años de experiencia en la industria de estructuras de membranas de tracción, hemos diseñado, diseñado, fabricado e instalado con éxito miles de proyectos de construcción de membranas de tensión de alta calidad en 37 países de todo el mundo. Las estructuras de tela extensible utilizadas como techado / cubierta / sombra / vela / marquesina para instalaciones deportivas, instalaciones de transporte, instalaciones culturales, instalaciones de paisajismo, instalaciones comerciales, cubierta de tratamiento de aguas residuales, tanques de almacenamiento de biogás, estructuras de membranas de aire, hoteles con estructura de membrana, domos geodésicos, etc. Nuestra estructura cumple con los estándares locales e internacionales de carga de viento y nieve. Nunca tomaremos riesgos cuando proporcionemos a nuestros clientes una estructura de membrana tensada que cumpla con los requisitos de carga de viento y nieve de cada región o país.

-

Fabricante profesional

Nos especializamos en proporcionar una gama completa de servicios, desde el diseño conceptual hasta la implementación del proyecto de estructura de tela.

-

Servicio de calidad

Brindamos un servicio rápido, de alta calidad y entusiasta, y la satisfacción del cliente es nuestra prioridad número uno.

-

Visión corporativa

La calidad es el salvavidas de nuestra empresa. Tenemos una estructura de tensión de 0 fallas en nuestros proyectos en los últimos 10 años.

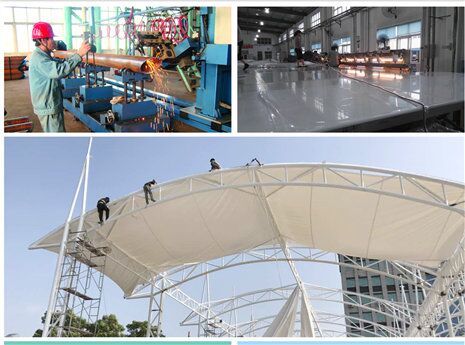

Fábrica de Procesamiento de Acero

La fábrica de procesamiento de estructuras de acero cubre un área de 3.000 m2. Cuenta con una máquina de corte de alambre de intersección CNC, máquinas biseladoras para doblado de tubos y un taller de acabado con torneado, fresado, cepillado y perforación. La capacidad de procesamiento anual de la estructura de acero es de 10,000 toneladas. Tiene la calificación de construcción de tres niveles de estructura de acero emitida por el departamento competente de construcción del estado.

Fábrica de Telas

La fábrica de procesamiento de membranas textiles tiene una superficie de 5.000 m2, con una capacidad de producción anual de 200.000 m2 de PTEF; una capacidad de producción anual de 100.000 m2 de ETFE; y una capacidad de producción anual de 300.000 m2 de PVC / PVDF. Tenemos la calificación de diseño y construcción de estructura de membrana. cción emitida por asociaciones industriales.

Centro de Noticias

Geodesic Dome Tents: A Visual Delight for Travelers Tensile Membrane Structures: Innovation, Aesthetics, and Performance What is a Tensile Fabric Structure? Why Load Analysis is Essential Sobre BDiR Inc.

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR specializes in cutting-edge stage membrane structures that transform events into unforgettable experiences. Designed for global clients, our solutions blend architectural elegance with engineering precision, creating iconic spaces for concerts, exhibitions, festivals, and corporate events.

-

Sleek & Functional Design: Customizable shapes and sizes to match any theme or branding.

-

Durable Materials: High-performance PVC or PTFE membranes ensure weather resistance, UV protection, and long-term reliability.

-

Rapid Installation: Engineered for quick setup and dismantling, ideal for time-sensitive events.

-

Sustainability: Eco-friendly materials and energy-efficient designs align with modern green standards.

Global Applications

From open-air music festivals in Europe to luxury product launches in the Middle East, BDIR structures adapt seamlessly to diverse climates and cultural needs. Our projects have elevated events worldwide, offering both visual impact and practical functionality.

Partner with BDIR

Elevate your next event with a stage that captivates. Contact BDIR to explore bespoke membrane structure solutions tailored to your vision.