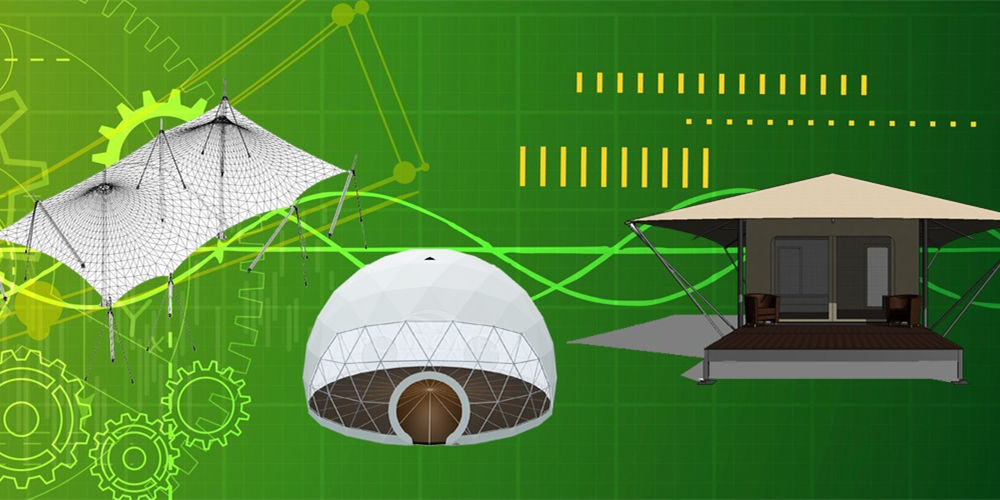

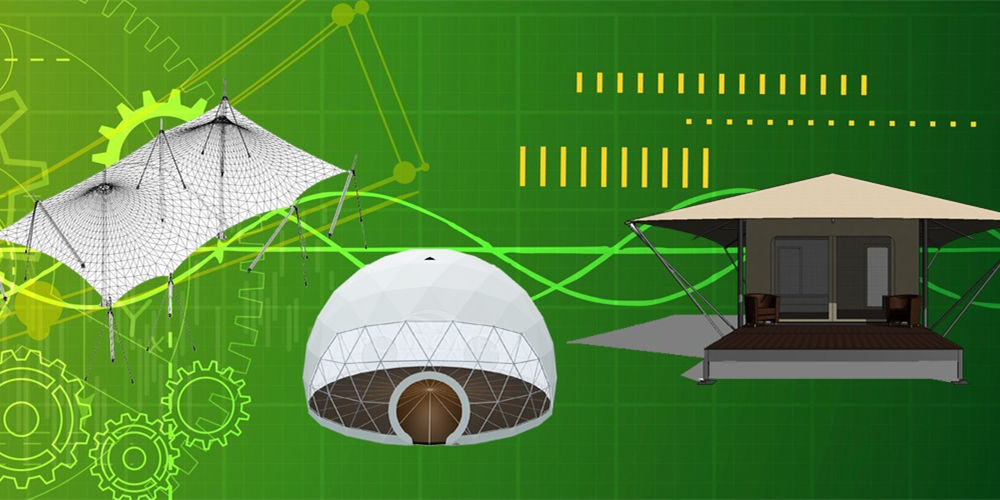

Professionelle Zugmembranstruktur Design & Hersteller

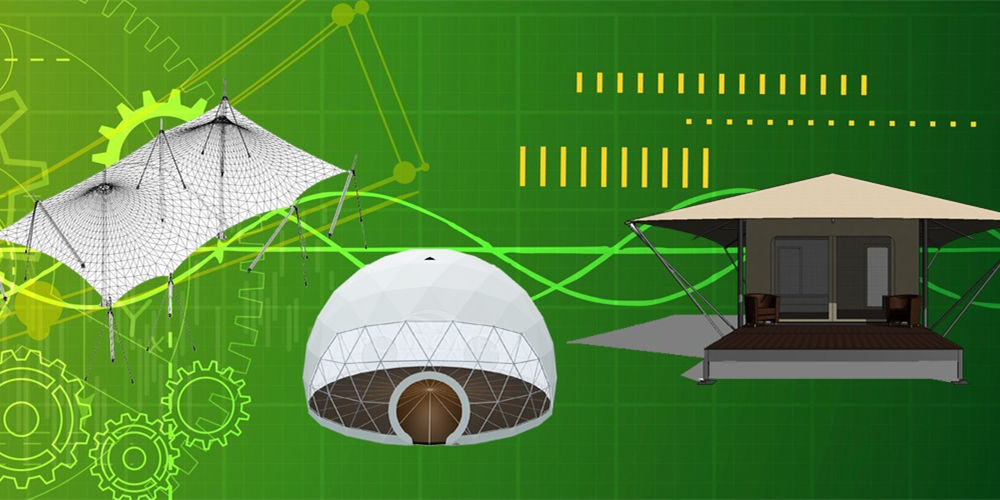

Mit unserer 10-jährigen Erfahrung in der Branche für zugfeste Membrankonstruktionen haben wir Tausende von qualitativ hochwertigen Spannmembrankonstruktionsprojekten in 37 Ländern auf der ganzen Welt erfolgreich geplant, konstruiert, hergestellt und installiert. Die als Überdachung / Überdachung / Schatten / Segel / Festzelt verwendeten Flächentragwerke für Sportanlagen, Transportanlagen, Kulturanlagen, Landschaftsanlagen, Gewerbeanlagen, Kläranlagen, Biogasspeichertanks, Luftmembranstrukturen, Membranstrukturhotels, Geodätische Kuppeln usw Unsere Struktur entspricht den lokalen und internationalen Wind- und Schneelastnormen. Wir werden niemals Risiken eingehen, wenn wir unseren Kunden eine gespannte Membranstruktur bieten, die den Wind- und Schneelastanforderungen der jeweiligen Region oder des jeweiligen Landes entspricht.

-

Professionelle hersteller

Wir sind spezialisiert auf die Bereitstellung einer umfassenden Palette von Dienstleistungen, von der Konzeption bis hin zur Implementierung von Stoffstrukturprojekten.

-

Qualitätsdienstleistung; Qualitätsservice

Wir bieten schnellen, hochwertigen und enthusiastischen Service und Kundenzufriedenheit ist unsere oberste Priorität.

-

Unternehmensvision

Qualität ist die Lebensader unseres Unternehmens. Wir haben in unseren Projekten in den letzten 10 Jahren eine 0-Fehler-Zugstruktur.

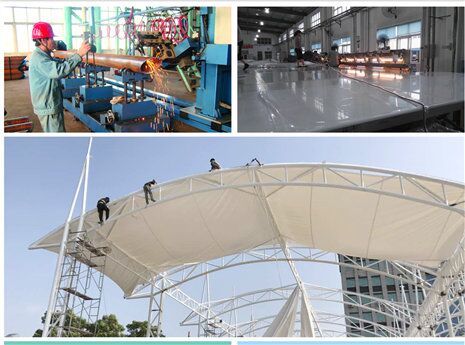

Stahlverarbeitungsfabrik

Die Fabrik zur Verarbeitung von Stahlkonstruktionen erstreckt sich über eine Fläche von 3.000 m2. Es verfügt über eine CNC-Schnittdrahtschneidemaschine, Rohrbiegemaschinen und eine Endbearbeitungswerkstatt zum Drehen, Fräsen, Hobeln und Bohren. Die jährliche Verarbeitungskapazität für Stahlkonstruktionen beträgt 10.000 Tonnen. Es hat die Qualifikation des dreistufigen Aufbaus der Stahlkonstruktion ausgestellt von der zuständigen Abteilung des Aufbaus des Staates.

Stofffabrik

Die Fabrik zur Verarbeitung von Gewebemembranen umfasst eine Fläche von 5.000 m2 mit einer jährlichen Produktionskapazität von 200.000 m2 PTEF. eine jährliche Produktionskapazität von 100.000 m2 ETFE; und eine jährliche Produktionskapazität von 300.000 m2 PVC / PVDF. Wir haben die Qualifikation für das Design und die Konstruktion von Membranstrukturen von Branchenverbänden herausgegeben.

Nachrichtenzentrum

Geodesic Dome Tents: A Visual Delight for Travelers Tensile Membrane Structures: Innovation, Aesthetics, and Performance What is a Tensile Fabric Structure? Why Load Analysis is Essential Company Culture Our Company Culture (Vision & Philosophy) Our Company Culture (Vision & Philosophy) Über BDiR Inc.

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR specializes in cutting-edge stage membrane structures that transform events into unforgettable experiences. Designed for global clients, our solutions blend architectural elegance with engineering precision, creating iconic spaces for concerts, exhibitions, festivals, and corporate events.

-

Sleek & Functional Design: Customizable shapes and sizes to match any theme or branding.

-

Durable Materials: High-performance PVC or PTFE membranes ensure weather resistance, UV protection, and long-term reliability.

-

Rapid Installation: Engineered for quick setup and dismantling, ideal for time-sensitive events.

-

Sustainability: Eco-friendly materials and energy-efficient designs align with modern green standards.

Global Applications

From open-air music festivals in Europe to luxury product launches in the Middle East, BDIR structures adapt seamlessly to diverse climates and cultural needs. Our projects have elevated events worldwide, offering both visual impact and practical functionality.

Partner with BDIR

Elevate your next event with a stage that captivates. Contact BDIR to explore bespoke membrane structure solutions tailored to your vision.