Profesyonel Çekme Membran Yapı Tasarımı ve Üreticisi

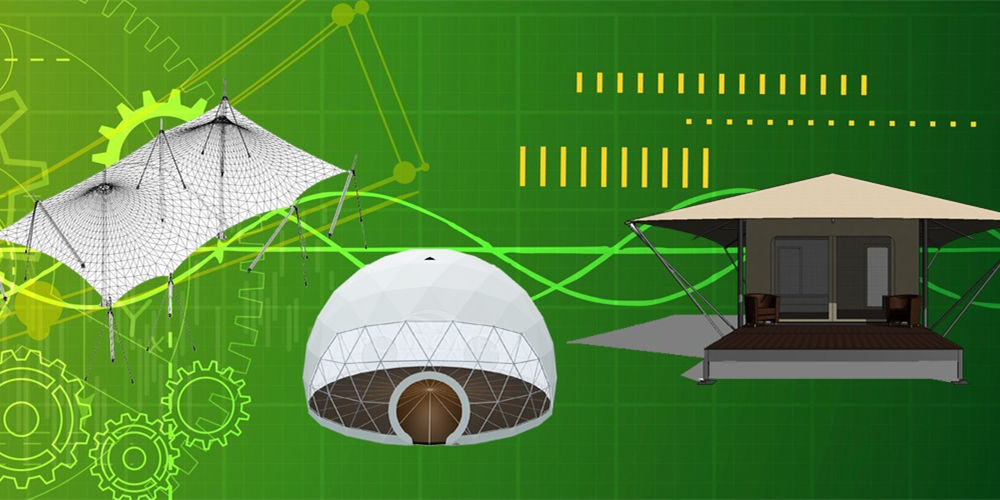

Çekme membran yapı endüstrisindeki 10 yıllık tecrübemizle, dünyanın 37 ülkesinde binlerce yüksek kaliteli gerilim membran konstrüksiyon projesini başarıyla tasarladık, ürettik, ürettik ve kurduk. Spor tesisleri, ulaşım tesisleri, kültürel tesisler, peyzaj tesisleri, ticari tesisler, kanalizasyon arıtma kanopisi, biyogaz depolama tankları, Hava membran yapıları, membran yapı otelleri, Jeodezik Kubbeler vb. Yapımız yerel ve uluslararası rüzgar ve kar yükü standartlarına uygundur. Müşterilerimize her bölgenin veya ülkenin rüzgar ve kar yükü gereksinimlerini karşılayan gergin bir membran yapısı sağladığımızda asla risk almayız.

-

Profesyonel üreticisi

Konsept tasarımdan kumaş yapı proje uygulamasına kadar geniş bir yelpazede hizmet sağlama konusunda uzmanız. .

-

Kalite servisi

Hızlı, kaliteli ve coşkulu hizmet sunmaktayız ve müşteri memnuniyeti birinci önceliğimizdir.

-

Kurumsal Vizyon

Kalitemiz, firmamızın yaşam çizgisidir. Son 10 yılda projelerimizde 0 adet hata çekme yapısına sahibiz.

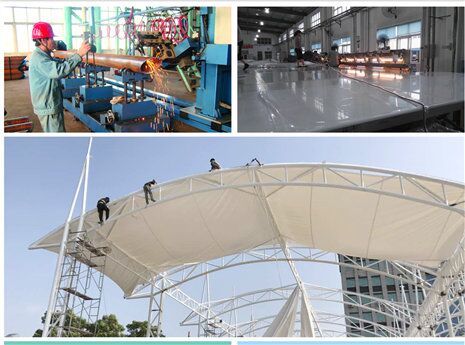

Çelik İşleme Fabrikası

Çelik yapı işleme fabrikası 3.000 m2'lik bir alanı kaplamaktadır. Bir CNC kesişen tel kesme makinesi, boru bükme makinesi eğme makineleri ve tornalama, frezeleme, planya ve delme ile son işlem atölyesine sahiptir. Yıllık çelik yapı işleme kapasitesi 10.000 tondur. Devletin yetkili inşaat departmanı tarafından verilen üç seviyeli çelik yapı konstrüksiyonu niteliğindedir.

Kumaş Fabrikası

Kumaş membran işleme fabrikası, yıllık 200.000 m2 PTEF üretim kapasitesi ile 5.000 m2'lik bir alanı kaplamaktadır; yıllık 100.000 m2 ETFE üretim kapasitesi; ve yıllık 300.000 m2 PVC / PVDF üretim kapasitesi. Membran yapı tasarımı ve konstrüksiyon yeterliliğine sahibiz endüstri dernekleri tarafından yayınlanan ction.

Haber Merkezi

Geodesic Dome Tents: A Visual Delight for Travelers Tensile Membrane Structures: Innovation, Aesthetics, and Performance What is a Tensile Fabric Structure? Why Load Analysis is Essential BDiR Inc. Hakkında

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR specializes in cutting-edge stage membrane structures that transform events into unforgettable experiences. Designed for global clients, our solutions blend architectural elegance with engineering precision, creating iconic spaces for concerts, exhibitions, festivals, and corporate events.

-

Sleek & Functional Design: Customizable shapes and sizes to match any theme or branding.

-

Durable Materials: High-performance PVC or PTFE membranes ensure weather resistance, UV protection, and long-term reliability.

-

Rapid Installation: Engineered for quick setup and dismantling, ideal for time-sensitive events.

-

Sustainability: Eco-friendly materials and energy-efficient designs align with modern green standards.

Global Applications

From open-air music festivals in Europe to luxury product launches in the Middle East, BDIR structures adapt seamlessly to diverse climates and cultural needs. Our projects have elevated events worldwide, offering both visual impact and practical functionality.

Partner with BDIR

Elevate your next event with a stage that captivates. Contact BDIR to explore bespoke membrane structure solutions tailored to your vision.