BDiR Inc. is a one-stop membrane structure service provider: experienced and professional. BDiR Inc. is a comprehensive membrane structure enterprise integrating tensile film, membrane structure engineering, membrane construction, space membrane, cable membrane design, processing and manufacturing, project installation and maintenance. We offer a full range of services from conceptual design to fabric construction projects.

Membrane Fabrication Process

BDiR Inc. membrane processing plant covers an area of 5,000 m2, with membrane inspection machine, imported automatic cutting machine, ETFE film fusion machine, PVC/PVDF fabric and PTFE membrane welding machine and other fabric processing equipment; PTEF annual production capacity of 200,000 m2; ETFE annual production capacity of 100,000 m2; PVC / PVDF annual productivity of 300,000 square meters. It has the qualification of membrane structure design and construction issued by the industry association.

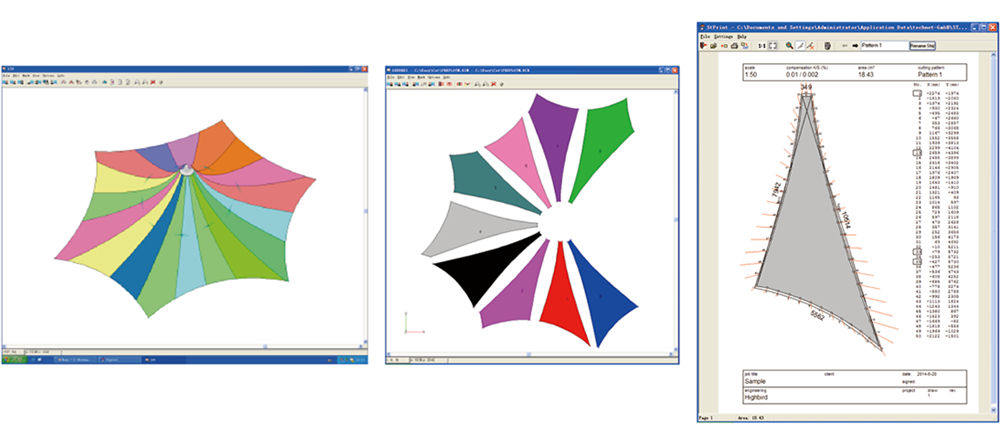

The membrane cutting design

1. membrane Cutting design principles

The membrane structure is a spatial membrane surface under prestressing. The purpose of the film cutting design is to use a fabric with no stress, flat state and width limitation to make the structures roof, so that the film surface conforms to the shape and stress distribution obtained after the drawing. The fine arrangement of the membrane welding seams is as important as saving the film material.

2. membrane cutting design steps

1). Arranging a cutting line on the membrane structures surface, and dividing the space membrane surface into a plurality of spatial membrane strips;

2). Expanding the space strip into a flat membrane strips;

3). Release the pre-stress and strain compensate the flat membrane (considering the elastic retraction of the film after the pre-stress release);

4). According to the above results, plus the amount of displacement at the seam of the diaphragm and the corners, a plane cut piece is obtained;

5). Finally, the processing drawing of the membrane are output.

stakeout, typesetting and cutting

The automatic stakeout is to input the data file containing the X and Y coordinates of each membrane into the computer, and then print it on the film cloth by typesetting and optimization, or cut the fabric membrane into pieces by a computer-controlled cutting machine. The accuracy of stakeout and cutting should be controlled within +/-2 mm.

heat sealing test and welding processing

Before the welding process, a heat sealing test is required to provide a parameter for membrane welding. The tensile strength of the test membrane strip shall not be less than 80% of the strength of the base metal. During the welding process, it is also necessary to periodically test and record the results so that the relevant parameters can be corrected at any time as the temperature and humidity of the environment change and the processing location is different.

For formal membrane welding processing, first align the diaphragm at the seam, check whether the front and back of the membrane and the seam sequence are correct; and cleaning the area to be welded. If it is a PVC fabric splicing joint, place a “back strip”; When the PTFE membrane welding, it is shall be placed with EFP strips between the two membrane layers. The welding machine is set according to the parameters obtained by the heat sealing test, and the membrane material is processed. Finally, according to the design drawings, the edges, corners of the membrane need to be reinforcement treatment such as rope, cable cuff.

When the membrane in heat sealing, a tension weld is used. A certain pre-tension is applied to the membrane to be welded to reduce the shrinkage of the membrane due to heat sealing and improve the stress state at the weld after the tension forming.

packaging

The designer needs to determine the unfolding direction of the membrane and the way of packaging according to the construction site and the installation equipment. After the membrane is cleaned on both sides, the membrane is folded and packaged according to the specified requirements. To prevent significant creases on the membrane, the PTFE fabric should be lined on a round paper tube when it is packes, and the ETFE film should not be folded and placed in a special protective container. The flexible package should be marked with the direction of deployment and placed in a wooden box for easy transportation.

the design and processing of the accessories

The accessory design closely related to the cutting mainly includes the film gusset design for the film corner, the selection of the connector and the determination of the length of the side cable.

The design of the membrane gusset plate mainly involves the form, size, angle, position and size of the connection hole and the mounting hole, the thickness of the plate, the connection mode of the membrane and the gusset plate, and the connection design of the side cable and the gusset plate.

According to the shape of the membrane surface and the stress at the corner of the membrane, the basic geometric parameters are determined, and the tensile strength, local pressure and weld length are checked, and the length of the joint and the side cable are calculated.

The membrane gusset plate should be simple, accurate in angle and smooth in force transmission. The membrane gusset plate is usually made of steel plate, hot-dip galvanized or made of stainless steel.